What is press fitting technology?

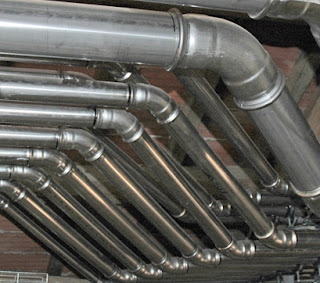

Press fitting technology is a method of tube joining that does not include the soldering method. Press tubes fittings are used to make a permanent tube joint, which is incredible water-tight. Press fittings do not require any kind of solvents or torches to work efficiently. They were introduced in the United States in 1995 and first pioneered by Viega. Press fittings have made the life of plumbing professional incredibly easy. Now the connection is made with the least efforts, and the professional achieve better durability in less amount of time. These have been improved with time as well. The first press fittings production line was known to be made up of aluminum and brass. It was later enhanced with the use of stainless steel and lead-free steel.

The benefits of using stainless steel

Although there have been a lot of variations in the press fittings technology, it would not be wrong if we highlight the significance of stainless steel. Stainless steel is the most preferred type of raw materials that have been used in joint-making tools. It is preferred because of the fact that it does not corrode or rust and is entirely compliant with health standards. In the section below, we would discuss some core advantages of Press Tubes Fittings Stainless steel:

1. Stainless steel has made the press fittings more robust

2. It can stand changing temperatures and weather fluctuations

3. It can resist moisture and humidity easily

4. It does not corrode or get rusted

5. It has no health alerts. Unlike copper, it maintains the healthiness of the water that passes through the connection

6. It is very durable and reliable

7. It is cost-effective such that you do not have to change the connection over and over again

8. It is also resistant to necessary chemicals - acids and alkalis.

Comments

Post a Comment